快速鏈接

系統(tǒng)概述

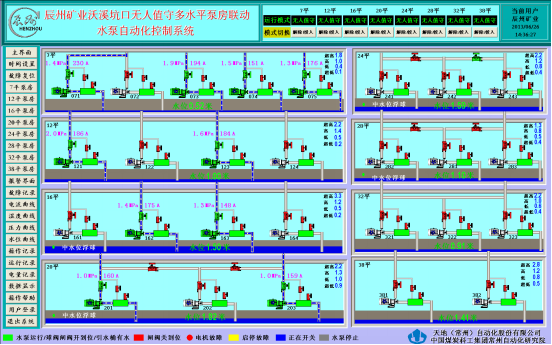

井下自動排水系統(tǒng)解決了井下排水系統(tǒng)自動控制的難題,利用現(xiàn)代最優(yōu)控制理論,分析礦井涌水情況和用電情況,建立了排水系統(tǒng)的離散數(shù)學模型根據(jù)最優(yōu)性原理,用動態(tài)規(guī)劃法,對排水系統(tǒng)進行分段決策控制,并提出通過遞推算法對數(shù)學模型進行求解,得出獲取最優(yōu)控制策略的一般方法。

井下自動排水系統(tǒng)具有以下特點:水位實時在線檢測并顯示各臺水泵自動啟動與停止,多臺水泵實行“輪班工作制”,提高水泵使用壽命;根據(jù)涌水量大小和用電“避峰就谷”原則,自動控制投入運行的水泵臺數(shù),與礦井監(jiān)控系統(tǒng)聯(lián)網(wǎng),便于集中控制。

System overview

The underground automatic drainage system solves the problem of automatic control of the underground drainage system. By using the modern optimal control theory, it analyzes the water gusher and electricity consumption of the mine, and establishes the discrete mathematical model of the drainage system. According to the optimal principle and the dynamic programming method, the drainage system is made up of subsection decision control, and the recursive calculation method is proposed to solve the mathematical model. The general method of obtaining the optimal control strategy is obtained.

The underground automatic drainage system has the following characteristics: real-time online water level detection and display of automatic start and stop of each pump, multiple pumps implement "shift work" to improve the service life of the pump; According to the amount of water inflow and the principle of "avoiding peak on valley", the number of pumps put into operation is automatically controlled, and the network of mine monitoring system is convenient for centralized control.

系統(tǒng)功能特點

水泵監(jiān)控子系統(tǒng)有四種工作方式,“無人值守”、“遠程自動”、“手動檢修”、“井下自動(一鍵啟停)”。無人值守:無人值守控制下,PLC采集各種信號,按照本水泵房的工藝流程及多水平聯(lián)動工藝,控制水泵及閘閥的開啟。由超聲波液位傳感器連續(xù)檢測水倉水位,結合浮球開關,自動開停水泵及其閥門。在正常水位時,各臺水泵能自動輪換工作,最大涌水及突出涌水時,自動投入必要數(shù)量的水泵運行。當水泵出現(xiàn)故障時,能夠及時報警,并能夠自動切換到開啟備用水泵。

根據(jù)水泵運行臺數(shù)以及水位變化率的情況來判斷礦井涌水情況,來確定水泵增加減少臺數(shù)。在“無人值守”工作模式下如果與井下通訊中斷,井下控制主機同樣會執(zhí)行無人值守模式。

遠程自動:調(diào)度中心的操作人員根據(jù)水倉顯示水位,確定開泵臺數(shù),在地面通過監(jiān)控主機人工手動開停水泵。可以通過監(jiān)控主機的一鍵啟停按鈕,一鍵完成泵組的抽真空、開泵、開閘閥,也可以單獨對閘閥、球閥、水泵進行控制。

手動檢修:井下操作臺旋鈕打到手動后,可操作任一水泵電機,閘閥的開關,此時地面監(jiān)控主機不允許對井下水泵房設備進行操作。

井下自動(一鍵啟停):井下操作臺旋鈕打到自動后,根據(jù)需要通過一鍵啟停旋鈕完成整個泵組的啟動過程。每臺水泵可設置“運行”、“備用”、“檢修”三種工作方式,該方式可直接通過本臺計算機進行設定。

System function characteristics

The pump monitoring subsystem has four working modes, "unattended", "remote automatic", "manual maintenance", "underground automatic (one-click start and stop)". Unattended: Under unattended control, PLC collects various signals, and controls the opening of the pump and gate valve according to the process flow of the water pump room and the multi-level linkage process. The ultrasonic level sensor continuously detects the water level of the water tank, combined with the float switch, the pump and its valve are automatically turned on and off. At normal water level, each pump can automatically rotate work, maximum water surge and prominent water surge, automatically put the necessary number of pumps into operation. When the water pump fails, it can alarm in time and automatically switch to open the standby water pump.

According to the number of pumps running and the rate of change of water level to judge the mine water gushing situation, to determine the increase and decrease of pumps. In the "unattended" working mode, if the communication with the mine is interrupted, the underground control host will also execute the unattended mode.

Remote automatic: the operator of the dispatch center determines the number of pumps to be opened according to the water level displayed in the water tank, and manually starts and stops the pump by monitoring the host on the ground. By monitoring the one-key start and stop button of the host, the pump group can be vacuumed, opened pump, and opened gate valve, and the gate valve, ball valve and water pump can also be controlled separately.

Manual maintenance: After the knob of the underground operation table is set to manual, the switch of any pump motor and gate valve can be operated. At this time, the ground monitoring host is not allowed to operate the equipment of the underground water pump room.

Downhole automatic (one-button start and stop): After the downhole operation table knob is turned to automatic, the whole pump group can be started by one-button start and stop knob as required. Each pump can be set up "running", "standby", "maintenance" three working modes, which can be set directly through this computer.